Tel: +86 532-88138566

Fax: +86-532-88138577

Mobile (Whatsapp/Wechat): +86-13792912185

Email: rock@qdantai.com

If the machine is not suitable for your workpiece, please tell us the following infromation:

What kind of workpiece will you clean?

What is the maximum size of the workpiece? (length, width and height)

What is the maximum weight of the workpiece?

What is the cleaning efficiency required?

According to your infomation, the most suitable machines will be designed for your workpieces.

Description

We can design and manufacture different size of steel plate pretreatment line according to customers' requirement. Please send your detail inquiry to our email. This type of steel plate auto blasting and coating machine is designed and produced by adopting the advantages of similar products from both within the country and abroad. The rusting cleaning part (shot blast cleaning) adopts high-efficient blast wheel and full shutter type shot sand separator. The sweeping machine adopts specially made high-strength nylon rolling brush and high-pressure ventilator. The preheating and drying part may adopt various heating methods. The paint spraying part adopts high-pressure airless spraying method. The complete set of equipment is controlled by PLC, and is the large-size complete equipment of international advanced.

This shot blasting machine and painting line is mainly used for surface treatment (namely preheating, rust removal, paint spraying and drying) of steel plate and various structural sections, as well as for cleaning and strengthening of metal structural parts. This machine is widely used in Shipyard, ship building industry, machinery industry, etc.

Application range

Antai QXY series steel plate pretreatment line is mainly used for surface treatment of steel plate and various type of structural steel (including preheating , rust removal, painting and drying, way of preheating can be optional as per users’ situation).

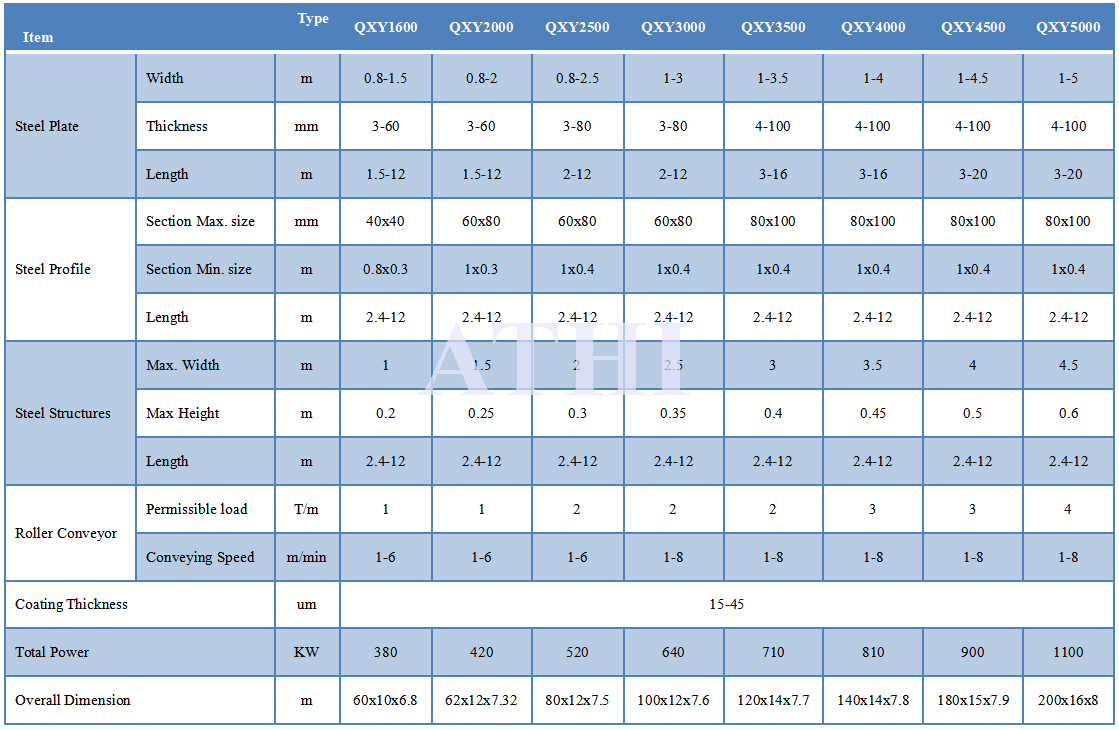

Technical parameter

Pictures

Feature

Solid Works 3D Design, support drawing review with customers, adequately satisfy requirement of customers.

PLC timing for service life of blasting equipment wearing parts, real time display and prompt replacement time automatically.

Preheating and drying adopts various ways of heating: electric heating, gas or fuel heating. Easy options according to users’ situation.

Painting adopts high pressure airless spraying method, USA Graco brand. Paint mist treatment meets environmental requirements.

PLC control, equipped with large Industrial Personal Computer, sub-console with touch screen.

We guarantee you that we do not store any more data than is required for the services provided. We do not pass this data on to third parties outside the qingdao zhenxiong Mechanical Equipment Co.,Ltd. All information will, of course, be treated confidentially.