Tel: +86 532-88138566

Fax: +86-532-88138577

Mobile (Whatsapp/Wechat): +86-13792912185

Email: rock@qdantai.com

If the machine is not suitable for your workpiece, please tell us the following infromation:

What kind of workpiece will you clean?

What is the maximum size of the workpiece? (length, width and height)

What is the maximum weight of the workpiece?

What is the cleaning efficiency required?

According to your infomation, the most suitable machines will be designed for your workpieces.

Description

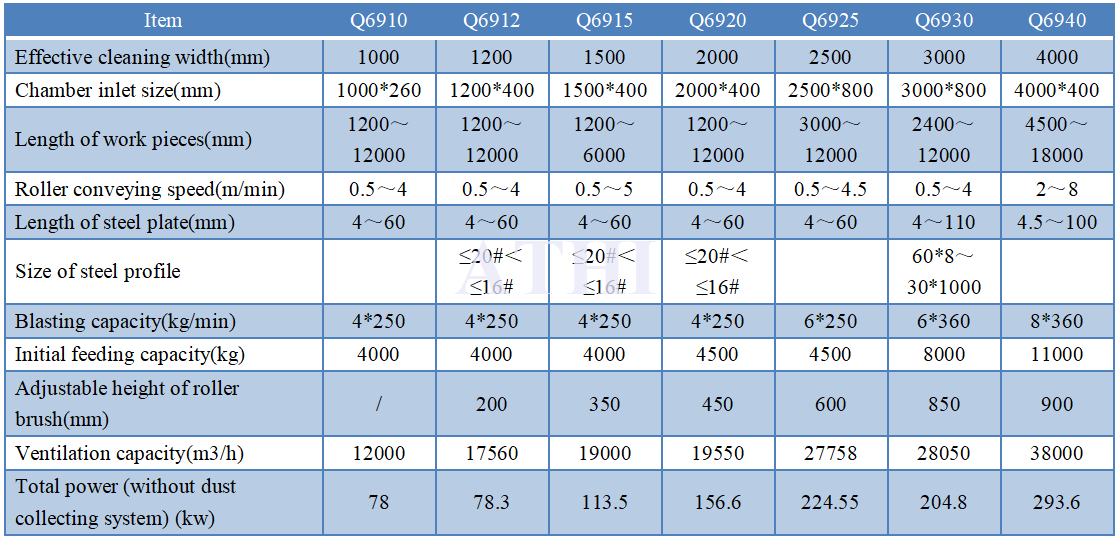

Roller conveyor machine is mainly used for processing long and (or) flat shape of the workpiece. These workpieces are continuously passed through the entering chamber, the shot blasting chamber and the cleaning chamber on a special conveyor roller table.

Qingdao ANTAI roller conveyor blast machines are designed as an optimal processing solution for steel plate/sheet metal, steel profile/beam/sections(H-beam, I beam, C-beam), steel pipes/tubes and steel structural framing, deformed steel bar etc, with residue from the shot’s abrasive action handled via a blowing and brushing system that ensures every last trace is removed.

With advice from our designers, you can decide to add a roller conveyor shot blasting system to your automatic treatment lines, including preheating, painting/coating and feed and transfer equipment.

In addition to the standard version of the roller conveyor blast machine, Qingdao ANTAI has produced the non-standard model, designed specifically for the customers' workpiece details.

Application range

process a wide variety of steel products such as plate, universal columns, beams, angles, flat, channel, bar, pipe, square and rectangle hollow sections.

Technical characteristics

Pictures

Variety of designs to clean complex fabrications or as rolled structural sections

Multiple turbine wheels clean from opposing directions providing optimum blast cleaning coverage

Rubber plate labyrinth sealing curtain in front and back sealing auxiliary chamber, effectively prevent abrasives from overflow.

Roller brush or high pressure air blow off to minimise abrasive media carry over

Safe interlocking in abrasives feeding device, blasting device and maintenance device, safe and reliable operation.

We guarantee you that we do not store any more data than is required for the services provided. We do not pass this data on to third parties outside the qingdao zhenxiong Mechanical Equipment Co.,Ltd. All information will, of course, be treated confidentially.