Tel: +86 532-88138566

Fax: +86-532-88138577

Mobile (Whatsapp/Wechat): +86-13792912185

Email: rock@qdantai.com

Description

V process casting machine is called vacuum seal casting molding machine. It’s a kind of dry sand casting molding machine which adopts no adhesive. Based on the pressure produced by the vacuum pump, it takes use of the EVA film to make a vacuum sealed condition. Then the dry sand will be tightened, and getting a mould. The finished casting’s quality is very good after pouring. Our V process casting machine has been ranked as Cleaner Production Directory because of its high sand recovery rate, high material utilization as well as its eco-friendly advantage. So far, V process has been successfully applied in the construction machinery counter weight, petroleum machinery(including crank, reduction case, counterweight), belt pulley, swing bolster, axle, brake drum, piano plane, manhole cover, high manganese steel lining board.

V process casting line is a kind of vacuum sealing molding casting process, also known as vacuum sealing molding method, called vacuum molding method or V method, also called as decompression moling method or negative pressure molding.

It uses a binderless dry sand as a molding material, seals a special sand box with a plastic film, and relies on a vacuum pump to extract the inner air, causing a pressure difference between the inside and the outside of the mold, so that the dry sand is compacted to form a desired The cavity is filled with molten metal to obtain a special casting method for the casting.

Production line structures

The whole casting production line is divided into two parts: sand processing unit and molding unit.

The main equipment of the sand reclamation unit includes: sand shakeout dust hood, sand shakeout grid and transition sand hopper, moulding box return roller , vibrating conveyor sand screen machine, suspended magnetic separator, plate chain elevator, sand storage, boiling cooling equipment, bucket elevator, belt conveyor, sand discharging device, dust collecting system, electric control system, etc.

The main equipment of the modeling unit includes: film laminating machine, film spreading platform, drying device, sand feeding system, mobile vibrating table, manipulator, core setting and moulding flat trolley, pneumatic control system, electric control system, hydraulic system, vacuum system,etc.

Brief introduction of V process molding line

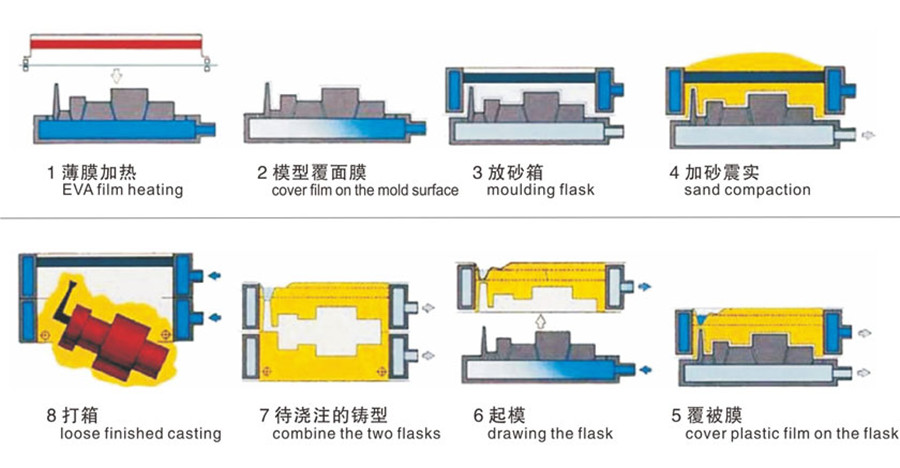

1. Film heating 2. Model covering film 3. Sand box 4. Sanding and compacting 5. Coating film 6. Molding out 7. Mold to be poured 8. Boxing

Principle of Vacuum process casting equipment

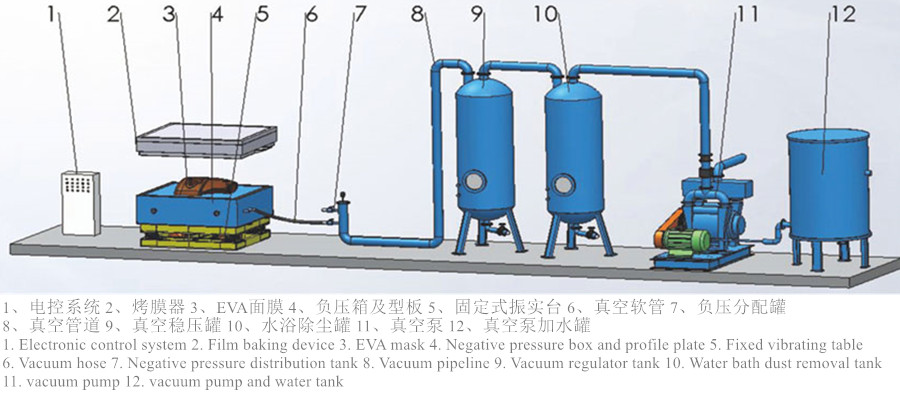

1. Electronic control system 2. Film baking device 3. EVA mask 4. Negative pressure box and profile plate 5. Fixed vibrating table 6. Vacuum hose 7. Negative pressure distribution tank 8. Vacuum pipeline 9. Vacuum regulator tank 10. Water bath dust removal tank 11. vacuum pump 12. vacuum pump and water tank

Product pictures

1. Castings with high dimensional accuracy and good surface finish.

2 Small weight deviation of castings.

3. Save raw material and high sand reclamation rate.

4. Long service life of pattern and molding box.

5. Low noise and low energy consumption.

We guarantee you that we do not store any more data than is required for the services provided. We do not pass this data on to third parties outside the qingdao zhenxiong Mechanical Equipment Co.,Ltd. All information will, of course, be treated confidentially.